In the dynamic world of logistics and supply chain management, warehouses play a pivotal role in ensuring the smooth movement of goods from suppliers to consumers. An essential component of this intricate process is “quality control”. But what exactly is quality control in a warehouse setting? Let’s delve into the details.

Understanding Quality Control in Warehousing

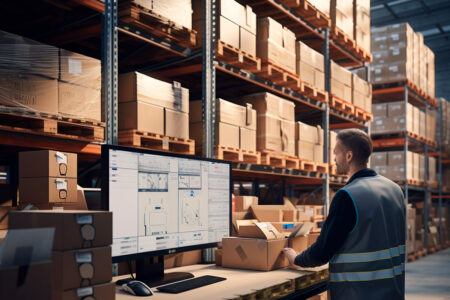

Quality control (QC) refers to the systematic procedures implemented to ensure that products meet the predetermined quality standards. In a warehouse, this encompasses inspecting incoming goods, storing them appropriately, managing inventory, and ensuring that outgoing products are in top condition.

- Incoming Goods Inspection: The first step in warehouse QC is inspecting the products that arrive from suppliers. This ensures that items are not damaged, expired, or of sub-par quality. The specifications might include checking for physical damages, verifying the quantity, or testing the product’s functionality.

- Proper Storage: Storing goods in a manner conducive to maintaining their quality is paramount. This could mean maintaining specific temperature or humidity levels for perishable goods or ensuring that sensitive electronics are stored away from areas with strong magnetic fields.

- Inventory Management: Efficient inventory management systems prevent overstocking or stockouts. Overstocking can lead to products getting expired or obsolete, whereas stockouts can disrupt the entire supply chain. An effective QC measure here is to use advanced inventory management software that tracks products in real time.

- Outgoing Goods Quality Check: Before goods are dispatched, they undergo a final quality check. This ensures that products sent to retailers or directly to customers are of the highest quality, free from damages, and adhere to the promised specifications.

Importance of Quality Control

Incorporating QC measures in warehouse operations brings several benefits:

- Enhanced Customer Satisfaction: Delivering high-quality products consistently boosts customer trust and satisfaction.

- Reduced Wastage: Efficient QC reduces the chances of defective products reaching the market, minimizing returns and waste.

- Optimal Inventory Levels: Regular checks and real-time tracking prevent overstocking and understocking, thereby reducing holding costs and potential sales loss.

- Risk Mitigation: Regular quality checks reduce the risks associated with selling defective products, which can result in legal actions or tarnish a brand’s reputation.

Quality Control at GoFreightHub

At GoFreightHub, quality isn’t just a buzzword; it’s an integral part of our ethos. We understand that in the logistics sector, ensuring consistent quality can be the difference between success and failure. Hence, we have embedded stringent quality control measures throughout our warehousing processes.

Our dedicated QC team is equipped with advanced tools and technologies to scrutinize every product that enters and exits our facilities. Additionally, our state-of-the-art inventory management systems guarantee that products are stored under optimal conditions, thereby preserving their quality.

Moreover, the culture of continuous improvement at GoFreightHub means that we are always looking for ways to enhance our QC procedures, ensuring that we not only meet but often exceed industry standards.

The Role of Technology in Quality Control

With the advent of advanced technologies like IoT (Internet of Things), AI (Artificial Intelligence), and Big Data, quality control in warehousing has undergone a transformative change. These technologies offer real-time tracking, predictive analytics, and automated quality checks, making QC more efficient than ever before.

For instance, sensors can track temperature and humidity levels in storage areas, ensuring perishable goods are stored under ideal conditions. AI algorithms can predict potential quality issues before they become significant problems, allowing warehouses to be proactive rather than reactive.

Conclusion

Quality control in warehousing isn’t just about ensuring product quality; it’s about safeguarding a brand’s reputation, ensuring customer satisfaction, and optimizing operational efficiency. Companies like GoFreightHub lead the way in exemplifying how a steadfast commitment to quality can lead to unparalleled success in the logistics sector. As we move forward, the integration of cutting-edge technologies will further revolutionize QC, making it an even more vital aspect of warehousing operations.